Shanghai Senci Automatic Control Equipment Co., Ltd. specializes in the maintenance and renovation of CNC bending machines, as well as the installation and renovation of laser safety protection for bending machines.

The SAFE100 safety module is a specialized safety module developed according to CE standards. It has a complete self diagnostic function, and the input/output circuit and CPU are dual redundant structures, ensuring that a single circuit fault will not cause the loss of safety functions. It comes with a pulse test power supply, which can automatically detect circuit faults and output status indicators.

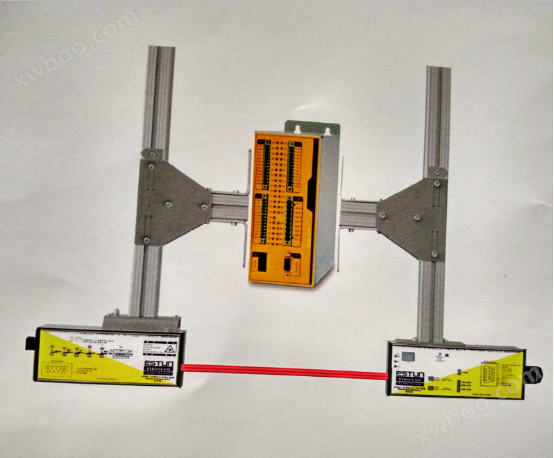

Bending machines belong to high-risk machinery in the mechanical processing industry. In order to prevent mechanical risks and protect equipment operators from harm, our country issued a new safety standard GB28243-2012 for bending machines in 2013, which requires mandatory implementation. According to the specific requirements of the GB28243-2012 national safety standard, we have launched a solution for the safety protection of bending machines that complies with the GB28243-2012 national safety standard. This plan is centered around the SAFE100 safety module and FPBS laser safety device, providing protective monitoring for safety risks during the operation of the bending machine. Providing FPBS for safety monitoring of the front operating position of the bending machine can ensure the efficiency of the bending machine and protect the operator from the risk of injury. Monitor the side and rear of the bending machine through the SAFE100 safety module to prevent personnel from entering the monitoring range and getting injured. At the same time, by monitoring the operation mode of the bending machine and the safety of the three positions of the on/off pedal, accidents caused by human error were avoided.